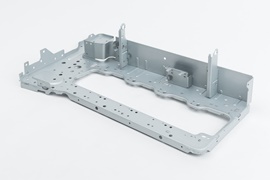

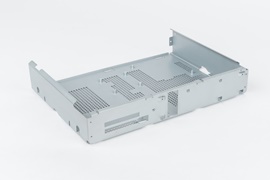

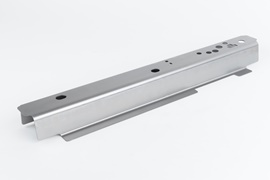

SHEET METAL STAMPING

Press stamping is Alphacast’s main sheet metal fabricating process. With the highest tonnage reaching 800 tons, most of its presses are of the high speed precision crankshaft type. There are also hydraulic presses suitable for deep drawing jobs as well as smaller mechanical presses to handle small or low volume parts.

Other fabricating processes include bending and shearing. Also machining, welding, heat treatment, polishing, silk screen printing, assembly and packaging may also be offered as secondary processes to add value to the products.

For maximum control and greater consistency in quality, Alphacast runs a complete tool and die department capable of designing and producing tools and fixtures. This self-sufficient engineering and tooling ability enables us to react promptly to a customer’s demand and makes possible the best quality of products be manufactured.

Most of Alphacast’s sheet metal fabricated products are components which are supplied to multinational companies in Thailand from the following industries :

- Auto accessories – Heat Insulator, Mounting Bracket, Metal component in car, etc.

- IT products – antenna receiver, monitor, printer, CD-ROM, hard disc drive, etc.

- Home appliances – air-conditioner, refrigerator, washer, etc.

- Hardware - Marine, Industrial, etc.

MARKET APPLICATIONS